Navigating New PFAS Testing Requirements for Wastewater Treatment Plants in Pennsylvania

New PFAS testing requirements are now in place for certain wastewater treatment permits in PA.

In February 2024, the Pennsylvania Department of Environmental Protection (PADEP) released new requirements for the analysis of PFAS at wastewater treatment plants, particularly those categorized as Major Sewage Facilities (average design flow greater than or equal to 1.0 million gallons per day (MGD), and/or have a service population greater than or equal to 10,000) and Industrial Permit Facilities (manufacturing, commercial, or other facilities which discharge industrial wastewater, alone or in combination with stormwater). These plants are now mandated to conduct PFAS (per- and polyfluoroalkyl substances) testing as part of their NPDES (National Pollutant Discharge Elimination System) permit renewals, and beyond.

PFAS compounds, known for their persistent nature and potential health impacts, have gained significant attention in recent years. The compounds added to the Permit Renewal Testing Requirements are PFOA, PFOS, PFBS, and HFPO-DA . Here’s a brief overview of each:

- PFOA (Perfluorooctanoic Acid): Originating from industrial processes and commonly found in products such as non-stick cookware and firefighting foams.

- PFOS (Perfluorooctanesulfonic Acid): Similar to PFOA, PFOS has industrial origins and has been widely used in various consumer products and firefighting foams.

- PFBS (Perfluorobutanesulfonic Acid): Used in a variety of industrial applications, including in the production of certain polymers and surfactants.

- HFPO-DA (Hexafluoropropylene Oxide Dimer Acid): A precursor to PFAS substances, often present in products such as stain-resistant coatings and firefighting foams.

PADEP clarified that there are different requirements for New Permit Renewals, and for Permit Renewals already in progress.

New Permit Renewals

As with the rest of the Group One contaminants required in the Permit Renewal package, facilities must test for these four PFAS compounds with three effluent samples, and one influent sample, and submit these results with their permit renewal application. The frequency of ongoing monitoring depends on the detection levels:

As with the rest of the Group One contaminants required in the Permit Renewal package, facilities must test for these four PFAS compounds with three effluent samples, and one influent sample, and submit these results with their permit renewal application. The frequency of ongoing monitoring depends on the detection levels:

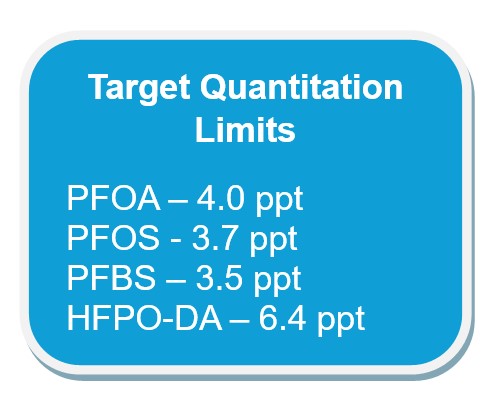

- For applicants with non-detect screening results at or below the Target Quantitation Limits (QLs), monitoring is required once a year.

- Applicants with detections or non-detects above the QLs will face quarterly monitoring requirements.

- However, there’s a provision for discontinuing monitoring. The permittee may discontinue monitoring for PFOA, PFOS, HFPO-DA, and PFBS if the results in 4 consecutive monitoring periods indicate non-detect results at or below Quantitation Limits of 4.0 ng/L for PFOA, 3.7 ng/L for PFOS, 3.5 ng/L for PFBS and 6.4 ng/L for HFPO-DA. When monitoring is discontinued, permittees must enter a No Discharge Indicator (NODI) Code of “GG” on DMRs.

Permit Renewals in Progress

For applications that PADEP already has received, or are in progress, PFAS testing may still be required.

PADEP provided additional clarifications for applications already in progress:

- Where there are indications there may be a possible PFAS source discharging to the POTW, such as the Industrial Waste types EPA believes to be sources (organic chemicals, plastics & synthetic fibers (OCPSF); metal finishing; electroplating; electric and electronic components; landfills; pulp, paper & paperboard; leather tanning & finishing; plastics molding & forming; textile mills; paint formulating, and airports) or sewage facilities that accept these sources), PADEP will likely require quarterly monitoring, with the possibility to remove the requirement if PFAS is absent after 4 (consecutive) non-detects.

- If an Industrial Facility facility with process wastewater discharges in one of EPA’s categories or if a major sewage facility that receives waste from an Industrial user in those categories has submitted their application, but a new permit has not been drafted yet, PADEP will impose quarterly monitoring.

- If an Industrial Waste facility with process wastewater discharges is not in one of EPA’s categories, or if a major sewage facility doesn’t receive waste from an IW in those categories, PADEP will impose annual monitoring instead of quarterly, starting now with permits that haven’t been drafted, even if sampling for PFAS parameters isn’t provided with the application.

It’s important to note that PADEP will provide a six-month grace period for the transition to the new permit requirements. However, as of August 5th, failure to submit PFAS results with the application will be considered a deficiency.

To comply with the new regulations, wastewater treatment plants must utilize EPA Method 1633 for PFAS testing. This method ensures accurate and reliable detection of PFAS compounds in wastewater samples. All samples should be performed as Grabs, not Composite.

These new PFAS testing requirements signify a proactive approach towards safeguarding environmental and public health in Pennsylvania. By adhering to these regulations and implementing appropriate monitoring measures, wastewater treatment plants can contribute to a cleaner and safer future for all.

When it comes to ensuring compliance with the latest environmental regulations, including the new PFAS testing requirements mandated by the Pennsylvania Department of Environmental Protection (PADEP), choosing the right testing partner is paramount. Here’s why wastewater treatment plants should consider Suburban Testing Labs for their PFAS testing needs:

- Accredited Expertise: Suburban Testing Labs is a highly accredited laboratory, holding certifications from organizations such as the Pennsylvania Department of Environmental Protection (PADEP), the U.S. Environmental Protection Agency (EPA), and the National Environmental Laboratory Accreditation Program (NELAP). Our team of experts possesses extensive experience in conducting PFAS testing using EPA Method 1633, ensuring accurate and reliable results.

- State-of-the-Art Facilities: Our laboratory is equipped with state-of-the-art instrumentation and technology, allowing for precise analysis of PFAS compounds in wastewater samples. We adhere to strict quality control protocols to maintain the highest standards of accuracy and reliability in our testing processes.

- Timely Turnaround: We understand the importance of timely results in regulatory compliance efforts. At Suburban Testing Labs, we prioritize efficiency and strive to deliver fast turnaround times without compromising the quality of our analyses. Our streamlined processes and dedicated team enable us to provide prompt results, helping our clients meet their regulatory deadlines effectively.

- Comprehensive Services: In addition to PFAS testing, Suburban Testing Labs offers a comprehensive range of environmental testing services to support the diverse needs of wastewater treatment plants. Whether it’s sampling for PFAS, testing for other contaminants, conducting compliance monitoring, or providing consultation services, we have the expertise and resources to assist our clients every step of the way.

- Client-Centric Approach: At Suburban Testing Labs, we prioritize customer satisfaction above all else. We understand the challenges faced by wastewater treatment plants in navigating complex regulatory requirements, and we are committed to providing personalized support and guidance to our clients throughout the testing process. Our dedicated client services team is always available to address any questions or concerns, ensuring a seamless and stress-free experience for our clients.

Suburban Testing Labs is your trusted partner for PFAS testing and environmental compliance needs. With our accredited expertise, state-of-the-art facilities, timely turnaround times, comprehensive services, and client-centric approach, we are committed to helping wastewater treatment plants achieve regulatory compliance and uphold environmental stewardship. Choose Suburban Testing Labs for reliable testing solutions you can trust.

Contact us today to learn more about our PFAS testing services and how we can support your compliance efforts.